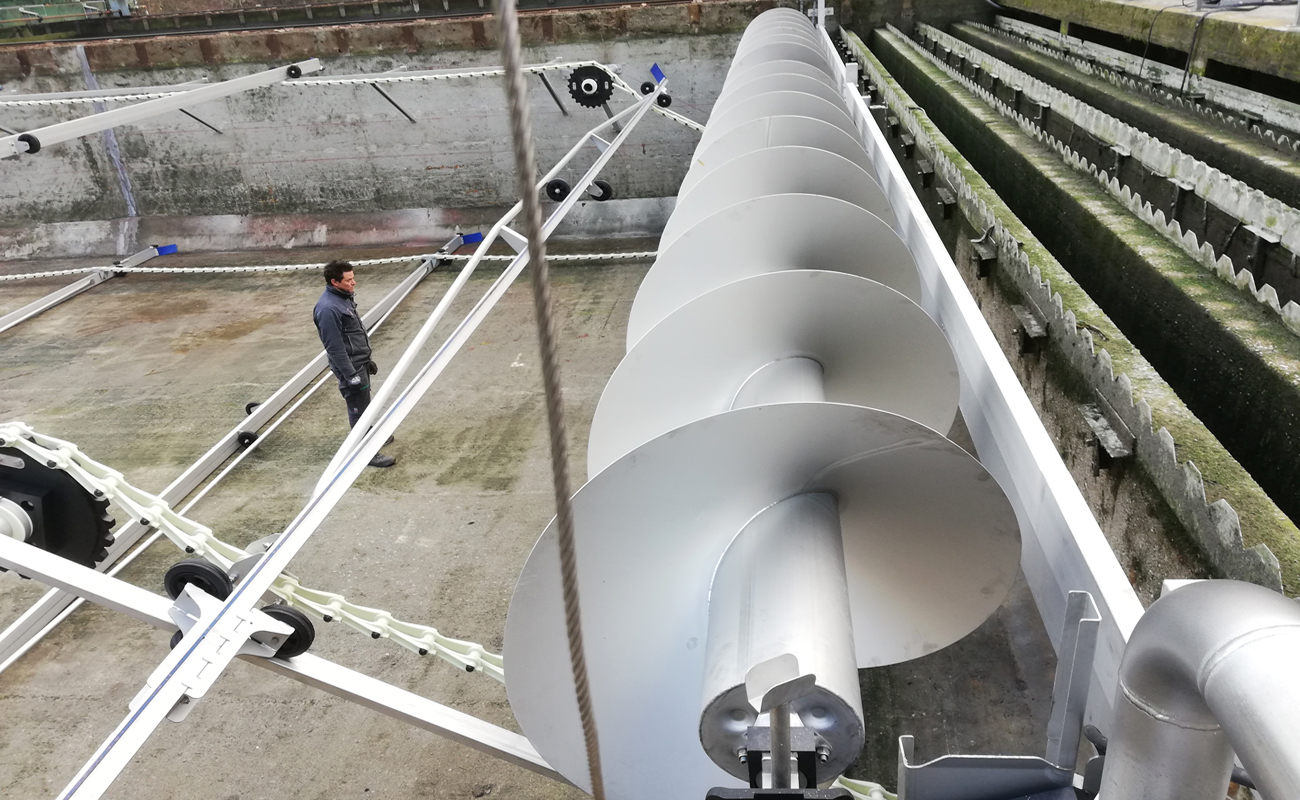

Plastic Chain Scraper KKR-L installed in a 13.6m wide sedimentation tank

Just before the end of the year 2020 Tschuda installed another KKR-L Plastic Chain Scraper: At the sewage treatment plant in Casnigo, close to Bergamo in Itlay, a 13.6m wide and 44.3m long final sedimentation tank was equipped with this special scraper system in combination with one Screw-conveyor Scum Remover SSR-2.

Together Tschuda and its Italian partner, Huber Technology srl, managed to finish the complete installation within the extremely short timespan of only 4 days.

After 6 systems of KKR-L – installed at the WWTP Trier in Germany – this is now another Plastic Chain Scraper designed as this special version for working in extremely wide sedimentation tanks.

Improved design for the rolling scraper flights

The well proven design principle with tight welded and weight-balanced scraper flights was kept. And as with the first 6 KKR-L systems, the carrying and also the lateral guide wheels have again been arranged further towards the center of the sedimentation tank than at systems working in “normal” tanks.

But the improved design of the scraper flights now ensures that their end wings are even more stably connected to the rest of the stainless steel beams. In this way, even more outstanding stability can be ensured for such particularly long scraper flights.

Low power rating at the drive motor

The drive unit is again provided with a gear motor having only 0.25 kW power rating, like it is typically used for all Plastic Chain Scrapers KKR. Due to the rolling design of the weight-balanced scraper flights and despite the low power rating, the drive unit still has a sufficiently large power reserve.

As the following rule is still valid for all moving bodies:

Rolling friction is lower than sliding friction, which is again lower than static friction!